Current Position:Home > APPLICATION

Application

Laser cutting is a slitting process with which it is possible to cut metallic and non-metallic raw materials of different material thicknesses. This is based around a laser beam which is guided, formed, and bundled. When it hits the workpiece, the material heats up to the extent that it melts or vaporizes. In this process, the whole laser power is concentrated on one point, with a diameter that is often less than half a millimeter. If more heat is introduced into this area than can dissipate through heat conduction, the laser beam will penetrate the material entirely - the cutting process has begun. While other processes involve applying large-scale tools with enormous power to the sheet metal, the laser beam completes its task without any contact. In this way, the tool does not incur wear, and no deformities or damage to the workpiece occur.

Advantages of laser cutting

Material Range

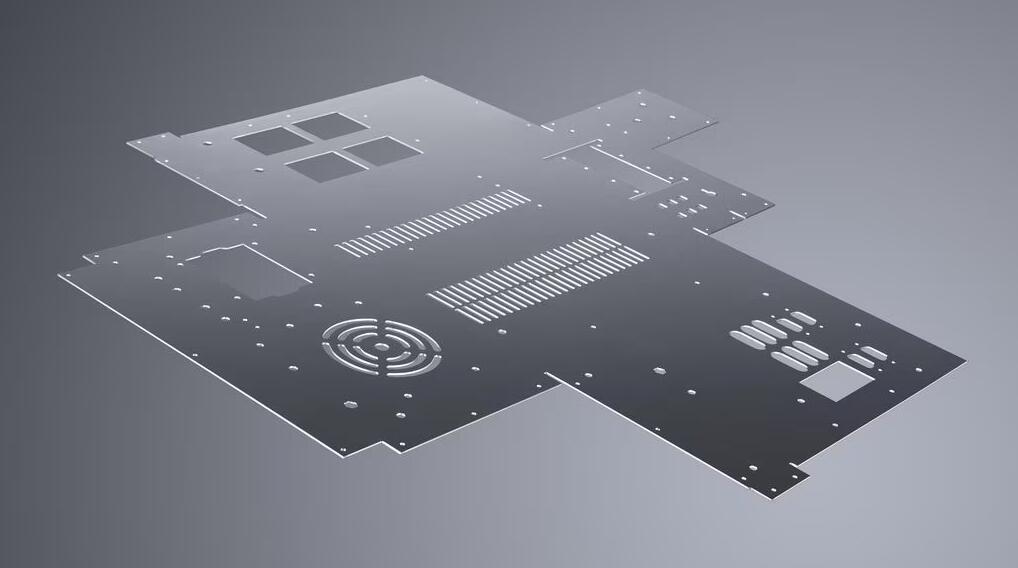

All materials common in industrial processing - from steel to aluminum, stainless steel, and non-ferrous metal sheets, all the way to non-metal materials such as plastics, glass, wood, or ceramics - can be cut safely and in high quality with the laser. Very different sheet thicknesses of 0.5 to over 30 millimeters can be cut using the tool. This extremely wide material range makes the laser the top cutting tool for many applications in the area of metals and non-metals.

Contour Freedom

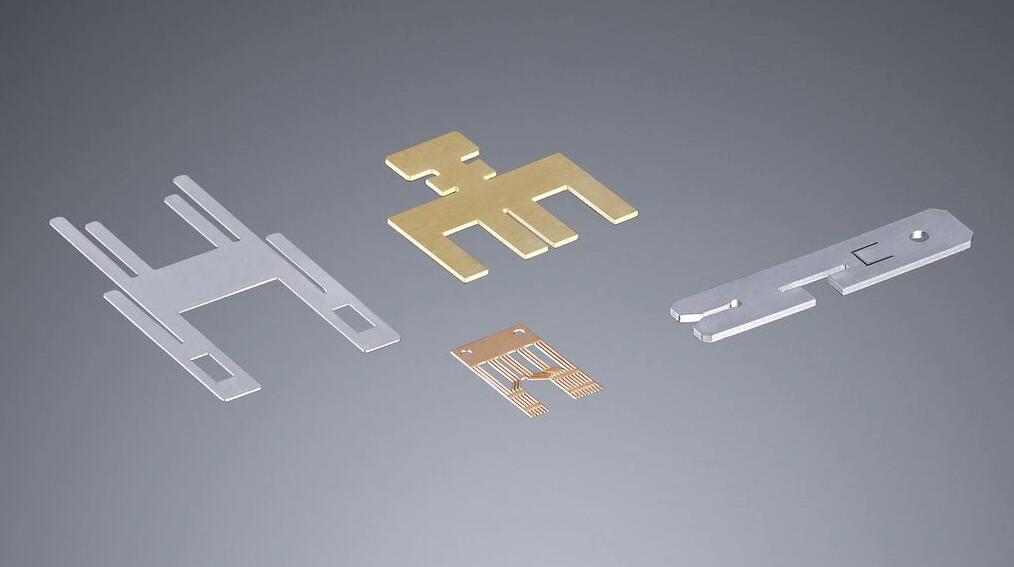

The bundled laser beam only heats up the material locally, and the rest of the workpiece is subjected to minimal thermal stresses or not at all. This means the kerf is barely wider than the beam and even complex, intricate contours may be cut smoothly and free of burrs. Time-consuming post-processing is no longer necessary in most cases. Due to its flexibility, this cutting procedure is often used for small lot sizes, large variant ranges, and in prototype construction.

High-Quality Cutting Edges with Ultrashort Pulses

Ultrashort pulse lasers vaporize virtually every material so quickly that heat influence cannot be detected, thereby creating high-quality cutting edges without ejection of melted material. This makes the lasers ideal for the manufacture of the most intricate metal products, such as stents for medical technology. In the display industry, ultrashort pulse lasers cut chemically hardened glass.