Current Position:Home > APPLICATION

Application

Whether it is for data matrix code identification marking of a component, for function-related markings on speedometers and shower heads or for customization of utility objects such as ID cards or cosmetic articles, their versatility is what distinguishes laser marking procedures above everything else.

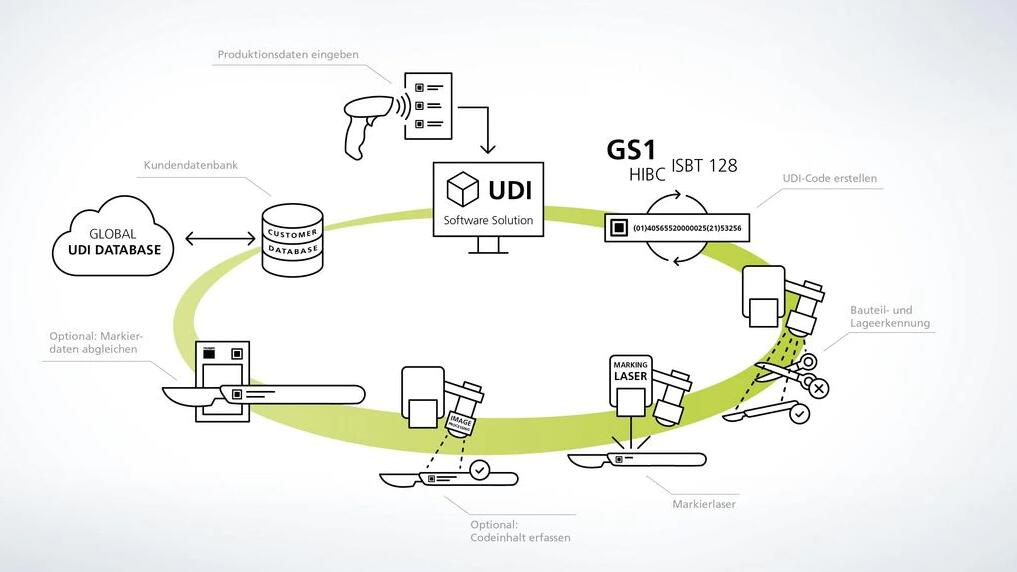

If that was not enough. Laser marking meets the more stringent demands on traceability and raw materials, for forgery protection and customized products. Laser marking can even satisfy the request to make a component its own storage medium for the Smart Factory.

How does laser marking work?

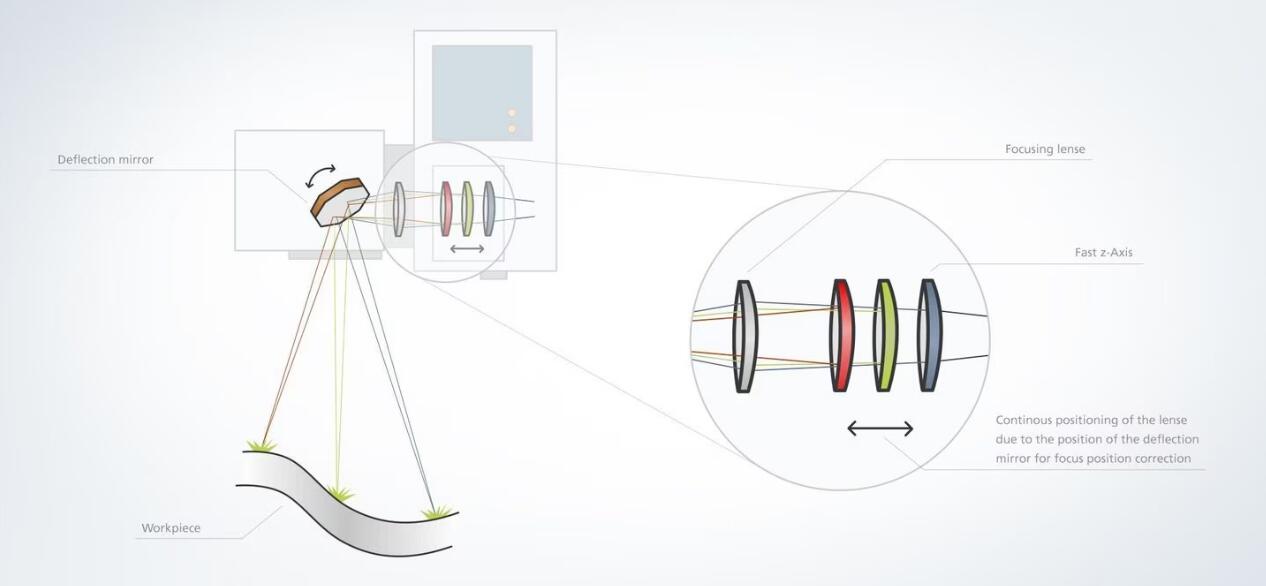

In laser marking, the marking is applied directly onto the surface using an intensive pulsed laser beam. The interaction of the focused beam with the surface leads to a change in the material - for example, discoloration, structuring, engraving or material removal.

The way the material changes depends largely on the wavelength of the laser, the pulse duration and the irradiance of the laser beam.

What are the advantages of laser marking?

Highly flexible

Whether it is metal, plastic or other materials: you can mark many materials and contents with the laser. Even large areas and points which are hard to access can be processed. In addition, elaborate steps for component preparation, such as cleaning with chemicals or polishing surfaces, are omitted. The laser does it in one process step.

High quality

Laser marking is distinguished by high contrast and sharp edges. Even the most detailed structures and micro markings can be applied without any problems.

Easy to integrate

Marking lasers are easily incorporated in (fully automated) production procedures and documentation systems. It is even easy to connect them directly with surrounding systems and databases, as well as check them directly thanks to integrated image processing systems.

Easy to customize

Whether it is design elements, names or your own markings - lasers make it easy to apply individual characteristics to products manufactured in standardized processes.