Current Position:Home > Products

Product Details

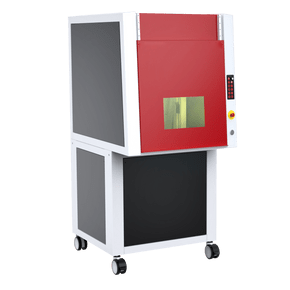

The use of HSW-650 laser marking machines supports automation processes through productive laser marking of dynamic data and extensive functionalities of AdvancedScripting®. Whether mechanical engineering, the electronics industry or contract engraving: You can mark individual components as well as large batches with a galvo laser system of laser class 2 for full traceability, brand communication or functional markings.

Be Productive Automated with the HSW-650 Laser Marking Machines.

The HSW laser software not only controls the laser process centrally, it also offers automation-compatible interfaces for connecting external data and control commands. Infinite scripting options guarantee consistent quality with recurring markings. The legibility of the marking is guaranteed by high quality lenses and components.

Be Productive Instantly with the HSW-650 Laser Marking Machines.

The HSW software boasts a graphically process-oriented interface. In this way, you can map marking processes visually without much prior programming knowledge. The integrated parameter database for various materials also helps to save time. This reduces your rejects to a minimum, both in series production and for custom-made products.

Be Productive Safely with the HSW-650 Laser Marking Machines.

The software and machine are designed to not only ensure simple and intuitive handling, but also full safety when handling the laser cell. The automated lift door, the rotary indexing table for a quick change of parts and the machine lighting and window concept create work ergonomics and productivity. All functions and productivity-increasing options always take maximum laser and machine safety into account.

Mark 100x Faster.

Mark inclined planes, spheres, bowls, cylinders and pipes up to 100x faster. Instead of rotating the 3D object mechanically, the focus is constantly guided over the object by a software-controlled lens system. Complex clamping, slow mechanical rotating and the time-consuming set-up associated with the mechanical rotary engraving attachment are no longer necessary thanks to the virtual rotary engraving.

Programmed by You.

Program your laser processes yourself. You can easily put together complex sequence programs, interactions with third-party systems or your own operator screens visually using predefined programming modules. In this way, system operators can set up new production processes quickly and without the help of manufacturer support and react quickly to changed requirements.

Mark everything That Needs to Be Marked.

Process data directly from Excel, SAP, E-commerce systems or databases. In this way, you can individualize separate parts automatically and with consistent data. You can do the programming and processing of all dynamic data directly in the laser software - without the help of third-party programs. From job shopper up to 10 pieces to mass production of up to 350 pieces per hour.

Full Process Integration.

Integrate your laser system into your automation environment. Both external control signals (e.g.: fieldbus automation) and external data (e.g.: serial numbers or codes) can be integrated using digital interfaces.

Designed for Process Reliability.

Rely on the system. Reliability, consistent quality, continuous operation and service friendliness are the focus. All components are designed for 24/7 use in industrial production.

Parameters

| HSW-650-1600 | HSW-650-1350 | HSW-650-1300 | HSW-650-700 Fiber | HSW-650-700RT | HSW-650-700 CO2 | HSW-650-300 | HSW-650-50 Fiber | |

|---|---|---|---|---|---|---|---|---|

| Maximum marking area | 51 x 18 in | 39 x 20 in | 39 x 18 in | 23 x 12 in | 312 x 12 in | 39 x 20 in | 7 x 7 in | 12 x 12 in |

| Max. workpiece height with F = 160 | 17 in | 27 in | 18 in | 19 in | 8 in | 15 in | 7 in | |

| Max. workpiece height with F = 254 | 12 in | 22 in | 13 in | 15 in | 8 in | 13 in | 2 in | |

| Overall dimensions (W x D x H) | 63 x 43 x 70 in | 51 x 52 x 80 in | 51 x 41 x 71 in | 31 x 39 x 71 in | 31 x 45 x 71 in | 31 x 47 x 71 in | 23 x 34 x 26 in | 15 x 31 x 26 in |

| Max. marking speed | 472 ips with F = 160 mm | 472 ips with F = 160 mm | 472 ips with F = 160 mm | 472 ips with F = 160 mm | 472 ips with F = 160 mm | 472 ips with F = 200 mm | 472 ips with F = 160 mm | 472 ips with F = 160 mm |

| Max. positioning speed | 472 ips with F = 160 mm | 472 ips with F = 160 mm | 472 ips with F = 160 mm | 472 ips with F = 160 mm | 472 ips with F = 160 mm | 472 ips with F = 200 mm | 472 ips with F = 160 mm | 472 ips with F = 160 mm |

| Laser power fiber | 20, 30, 50 W | 20, 30, 50 W | 20, 30, 50 W | 20, 30, 50 W | 20, 30, 50 W | 20, 30, 50 W | 20, 30, 50 W | |

| Laser power MOPA | 20, 100 W | 20, 100 W | 20, 100 W | 20, 100 W | 20 W | 20, 100 W | 20, 100 W | |

| Laser power CO2 | 60, 120 W | |||||||

| Laser class | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 4 |

| Weight | 500 kg | 580 kg | 400 kg | 260 kg | 300 kg | 260 kg | 77 kg | 62 kg |

| Max. loading | 50 kg | 50 kg | 50 kg | 50 kg, with y-axis 30 kg | 20 kg | 50 kg | 25 kg | |

| X-axis | standard | standard | standard | optional | standard | optional | ||

| Y-axis | standard | standard | optional | optional | optional | optional | ||

| Z-axis | standard | standard | standard | standard | standard | standard | standard | standard |